When it comes to insulating your home, spray foam is one of the most efficient and effective options available today. However, with different foam types, installation methods, and product qualities to evaluate, choosing the right spray foam insulation requires careful consideration. Let’s walk you through the key factors in selecting the best spray foam insulation for your particular home and project.

Understanding Spray Foam Insulation

Before diving into the specifics of selecting spray foam insulation, let’s review the basics of what spray foam is and why it’s a top insulation choice.

What is Spray Foam Insulation?

Spray foam insulation is created by combining two liquid chemical components to expand and form rigid foam plastic. The liquids consist of isocyanate and resin blends which react when mixed at the application site using specialized spray equipment.

As the liquids expand 30-60 times their original volume, they fill cracks and voids while curing into foam plastic. This manufactured foam insulation is very different from more common batt and blown-in insulations made of fiberglass, cellulose, wool, or cotton.

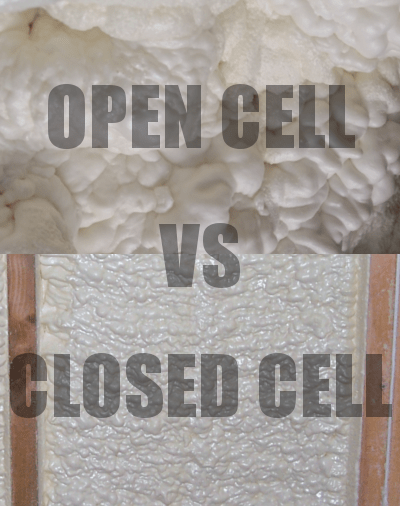

Spray foam insulation is available in two main types – open cell insulation and closed cell spray foam insulation – which have different properties suited to particular applications.

What is Open-Cell Insulation?

Open-cell insulation is made from small, lightweight foam bubbles. The bubbles are filled with air, which allows air to circulate through the material. This type of insulation works by slowing down heat transfer and air infiltration. Open-cell insulation is effective for insulation but less effective as a vapor barrier.

What is Closed-Cell Insulation?

Closed-cell insulation is made from compact foam with densely packed air bubbles. The closed cells trap insulating gas to resist heat flow and air infiltration. This type of insulation works as an effective moisture and vapor barrier. Closed-cell insulation has a higher R-value per inch compared to open-cell insulation.

The Importance of Spray Foam Insulation

There are several reasons spray foam has become an increasingly popular and important insulation material:

- It can provide a superior R-value up to R-7.4 per inch, giving powerful thermal resistance in less space.

- The expanding foam seals cracks and gaps that cause energy-wasting air leaks exceptionally well.

- Spray foam insulation adds structural stability and rigidity when applied to walls and roofs.

- It resists moisture accumulation and mold growth better than other insulations.

- Certain types of spray foam offer vapor control and condensation prevention.

- The long-lasting, durable foam retains its insulation value for decades.

- It suits hard-to-insulate places like attics, crawlspaces, and oddly shaped areas.

How Does Spray Foam Insulation Work?

Spray foam insulation is a very effective method of insulating buildings because it has the ability to insulate and air seal at the same time. This dual-action makes it superior to other types of insulation.

When spray foam is initially sprayed into place, it is a liquid that expands rapidly, filling every nook and cranny before curing into a rigid foam plastic. As it cures, it adheres tightly to the surfaces it’s sprayed onto, forming a continuous barrier that resists conductive, convective, and air infiltration heat transfer.

The expanding foam fills in any cracks, gaps, and voids as it sprays, acting as a sealant against air leaks. This air sealing ability stops drafts and regulates indoor temperatures. Air leakage can account for up to 40% of energy loss in a building, so by blocking these paths for air infiltration, spray foam reduces heating and cooling costs.

Once cured, the rigid foam plastic is filled with millions of tiny, separated air pockets. These small air pockets resist conductive heat flow through the insulation and convective heat transfer by air movement within the foam. The more compact the foam cells, the better its insulative properties.

Closed-cell spray foam, with its dense structure of tiny foam bubbles, provides an insulation value of R-7.4 per inch.

In addition to the insulative air pockets, the rigid foam plastic itself resists conductive heat flow. Heat energy requires a medium to transfer, and foam plastic provides a barrier that slows the rate of thermal conduction through building materials. The thicker the spray foam insulation, the more limited the conductive heat transfer.

By adhering tightly to surfaces, expanding into crevices, and remaining rigid after curing, spray foam physically blocks points where air infiltration and conductive heat transfer can occur. This mechanical insulation reinforces the insulative properties of the foam itself.

Certain spray foam formulations are also effective vapor retarders. When water vapor hits the closed-cell structure of spray foam, it condenses rather than penetrates through the insulation. This property blocks moisture from accumulating in building cavities, protecting against structural issues.

Factors to Consider When Choosing Your Spray Foam Insulation

When selecting the right spray foam insulation for your particular project, there are several important factors to take into account:

Insulation Value

A key consideration is the R-value or insulation strength provided per inch. Most spray foam insulation provides an R-value between R-3.5 to R-7.4 per inch of thickness. Closed cell spray foam generally insulates better than open cell.

Consider the insulation thickness required for the climate zone and your goals. Aim for an overall R-value appropriate for your region when installed at the desired thickness.

Project Size and Scope

The size of the insulation project and details like whether it is new construction or a retrofit also affect material choice. Closed cell foam is often preferred in areas such as a crawl space or basement where moisture is a concern. In larger areas such as attics and walls, open cell foam can be an economical option.

Accessibility requirements and desired structural enhancement can also dictate foam type needed. Evaluate how foam will be applied when selecting insulation.

The Process of Installing Spray Foam Insulation at Home

Understanding the process of properly installing spray foam insulation is helpful for planning your project:

Safety Measures to Consider Before Application

- Ventilate the space well before, during, and after installation to prevent fume buildup.

- Post warning signs and restrict access to the spray area to protect household members.

- The install team should use proper protective gear like masks, goggles, and gloves.

- Cover any nearby surfaces not receiving foam to prevent overspray.

- Confirm electrical and HVAC components are turned off before starting.

Step-by-Step Process of Installation

- Inspect and prepare the spraying surfaces for adhesion.

- Mix foam precursor components using specialized proportioning equipment.

- Apply foam in multiple passes of 1⁄2 inch layers until reaching the thickness needed.

- Let foam fully expand before adding additional passes.

- Trim any excess foam and remove protective masking and sheeting.

- Clean spray equipment thoroughly after completing application.

Post-Installation Care and Maintenance

- Allow 24 hours for full off-gassing and curing before occupying the space. Continue ventilating.

- Regular cleaning or painting is not necessary but can enhance aesthetics.

With proper installation and curing time, the foam should provide decades of high-performance insulation.

Professional Spray Foam Insulation Services: Why They May Be Your Best Option

While DIY spray foam insulation kits are available, hiring professional spray foam insulation services brings expertise and experience that is often worth the investment:

The Cost of Hiring Professional Insulation Services

Professional spray foam insulation costs can vary per square foot. The exact rate depends on factors like your location, chosen foam product, project size, and house specifics that dictate labor time and complexity.

Many foam installers offer free estimates to provide accurate pricing for your particular project. This allows you to budget appropriately.

Value of Hiring Professionals

Professional spray foam installers offer value beyond just labor. Their key advantages include:

- Greater experience and training for proper application technique.

- Access to wider range of commercial-grade foam products.

- Ability to determine the optimal foam type and thickness for your needs.

- Equipped with large spray rigs to cover large areas efficiently.

- Familiar with building methods and codes to ensure compliance.

- Reduce risks of overspray or cleanup issues in your home.

For most homeowners, hiring a pro is worth the price for superior results.

Evaluating the differences between spray foam formulations, hiring professional services when prudent, and following proper handling procedures allows homeowners to maximize the benefits of spray foam insulation while minimizing risks. Focus on choosing the optimal spray foam insulation for your climate needs, project scope, and budget. With diligent product selection and installation, you can enjoy enhanced comfort, energy savings, and durability.

Trust Cincinnati RetroFoam for Spray Foam Insulation

When it comes to spray foam insulation in Cincinnati homes and buildings, there’s one company you can trust – Cincinnati RetroFoam.

As a local company rooted in Cincinnati, we understand our climate, older housing stock, and the benefits spray foam can offer. We offer top-quality open and closed cell foam solutions to match your project. This leads to optimal energy efficiency and comfort improvements. From start to finish, you can rely on our team of seasoned professionals to implement spray foam insulation right. We take care of assessing your existing insulation, determining ideal spray points and installing the foam throughout cavities.

If you’re looking to finally upgrade your home’s insulation with spray foam, look no further than the experts at Cincinnati RetroFoam. Our tailored solutions, outstanding service, and results you can count on make us the smart choice for foam insulation.

FAQs

What is the R-value of spray foam insulation?

Typical R-values range from R-3.5 to R-7.4 per inch. Closed cell foams have a higher R-value than open cell in less thickness.

Does spray foam need additional vapor barriers?

Closed cell spray foam acts as its own vapor barrier when installed at sufficient thickness. Open cell foam requires a separate barrier.

Is spray foam environmentally friendly?

Many modern spray foams utilize eco-friendly blowing agents with low global warming potential and off-gassing.